Saharanpur, Uttar Pradesh

Dairy and Milk Processing Plant Machine

Leading Manufacturers, Exporters, Wholesaler and Retailer of Balance Tank, Butter Churner, Butter Melting System, Butter Transfer System, Can Scrubber, Dump Tank, Ghee Boiler, Milk Pasteurizer, Milk Plant Falling Film Evaporator, Milk Storage Tanks and Silos, Milk Transfer Pump, Milk Weigh Bowl, Paneer and Cheese Press Machine, Powder Mixing Venturi Machine, Roller Conveyor, Stainless Steel Amul Trap and Stainless Steel Paneer Vat Machine from Saharanpur.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Season | Summer, Winter |

| Feature | Anti-Wrinkle, Breath Taking Look, Comfortable, Easily Washable |

| Pattern | Plain |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Capacity | 500 litres/hr |

| Dimension | 6.5x4.3x10.6 inch |

| Automatic Grade | Manual |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

Our offered churner is extensively used for the conversion of butter from cream in the food processing industry. It is designed and developed in accordance with the specifications provided by our valued clients, this range is highly acclaimed across the globe. The churning is the process of shaking the cream to produce butter. The range possesses beneficial features like durability, reliability, and trouble-free operations. Our Butter Churners are well known for their quality and durability. To ensure its flawless performance the device is well tested in the different states. Able Engineering is the leading manufacturer of Butter Churner and complete milk plants and dairy plants and milk plants and dairy plants equipment manufacturers in India.

- Functioning is smooth.

- Durable in nature.

- Trouble-free operation.

- Functionality is easy and safe.

- Robust construction.

- Sturdy design.

- Hygienic butter processing environment

- Minimum maintenance.

- Easy to clean.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Certification | CE Certified |

| Weight | 10-100kg, 100-200kg |

| Feature | Accuracy, Easy Insatallation, Easy To Use, Low Consumption |

| Number of Conductors | 10-15 |

| Power | 1-10kw, 10-20kw |

| Driven Type | Electric |

| Warranty | 1year |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

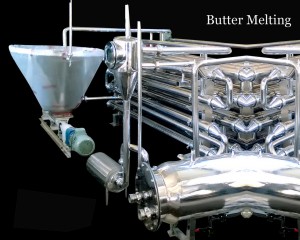

Able Engineering designs and fabricates an ergonomically designed, self-contained melting system to reduce manual lifting and dumping, and improve employee safety. Our systems also include many other special features to ensure easy maintenance and reduced labor. It can be of great benefit to use the improved techniques and improve the business productivity. Our melting system is ideal for melting butter. Our system is of extreme quality material as the design is made with perfection. It has a hot water coil structure which makes the cleaning go with ease. The product works timber-based which allows the dosing operations to be carried with perfection. Also, it is best for making yogurt.

Able Engineering can provide you these systems in different standard capacities, which allows you to get the machinery in different configurations. Able Engineering is the leading manufacturer of Butter Melting Systems and complete milk plants and dairy plants and milk plants and dairy plants equipment manufacturers in India.

Basic functions

- The make of butter melting vat is of stainless steel material which makes it the first preference for customers.

- Double jacket for product indirect heating.

- Gear motor is mixed with the blade.

- The panel which runs through electricity is used to control the equipment.

- The machine as per the industry standards which allows to carry out the work with ease.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Certification | CE Certified, ISO 9001:2008 |

| Weight | 0-100kg |

| Power | 1-3kw, 3-5kw |

| Driven Type | Electric |

| Warrenty | 1year |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

Able Engineering is the leading manufacturer of Butter Transfer System and complete milk plants and dairy plants and milk plants and dairy plant equipment manufacturers in India. Butter Transfer System used for transfer butter for further process and It placed at the bottom of butter churner. The Hot water-jacketed helps the butter to melt and formed into a vessel. The screw in the bottom transfers it for further process.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Certification | CE Certified, ISO 9001:2008 |

| Application | Scrubbing |

| Weight | 100-1000kg |

| Voltage | 380V |

| Power | 1-3kw, 3-6kw |

| Driven Type | Electric |

| Warranty | 1yrs |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

In Dairy Industry Can Scrubbers are very well in demand by different names like Can Washer, Milk Can Cleaner, Milk Can Cleaning Machine, etc. Milk Can Scrubber Machine that is used for cleaning the cans from both inside and outside mechanically. To ensure its superior performance and smooth operation, our team of veteran professionals has manufactured the offered can scrubber utilizing the top-notch grade components as per set industry standards. Our Milk Can Scrubber Machine is widely accredited for its rugged construction, easy maintenance, and longer service life. The can scrubbers are widely appreciated by our clients for their durability and sturdiness. Able Engineering is the leading manufacturer of Can Washer, Milk Can Cleaner, Milk Can Cleaning Machine, and complete milk plants and dairy plants and milk plants and dairy plants equipment manufacturers in India.

Features

- Compact design.

- Optimum performance and smooth operation.

- High performance.

- Consume less time.

- Rust-proof nature and long-life durability.

- Easy to use.

- Less maintenance and easy installation.

- Rugged construction and fine finish.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Storage Capacity | 200 Liter |

| Body Material | Stainless Steel |

| Grade | SS 304 |

| Finish | Coated |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

The Dump Tank fabricated from SS 304 (2 thk.) will be located under the milk reception weigh bowl to collect the milk as it is released from the weighing bowl. The main purpose of the dump tank is to store and/or transport bulk products from one place to another. Having a cylindrical shape, these durable and weather-resistant dump tanks have a conical bottom, top cover type with drain valve. Castor wheels are also provided as per the requirements of our customers. Able Engineering is the leading manufacturer of dump tanks and complete milk plants and dairy plants and milk plants and dairy plants equipment manufacturers in India.

Features of SS Milk Dump Tanks

- Castor wheels are provided to ensure easy transportation.

- Superior-grade stainless steel for maximum sturdiness and strength.

- Robust Construction.

- Leak-proof storage and transportation of milk.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Design Type | Customized |

| Capacity | 50 to 500 Ltr. |

| Surface | Polished |

| Color | Silver |

| Frequency | 50 Hz |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

Ghee Kettle (Ghee Boiler) is used for making high quality and pure ghee from butter. Able Engineering has expertise in offering Ghee Kettles for Ghee Units. These boilers are very effective for boiling a large amount of ghee. These comprise three jacket finish which we fabricate using SS 304 material. For hot thermic fluid flow, We design it with a protective jacket and to prevent heat dissipation also provide an outer jacket for insulation. We make complete Ghee Units for the milk plant. We offer these boilers in a customized capacity as per the client’s requirement. Able Engineering is the leading manufacturer of Ghee Kettle (Ghee Boiler) and complete milk plants and dairy plants and milk plants and dairy plant equipment manufacturers in India.

- Rust resistance.

- Long service life.

- Robust construction

- Fine finish.

- Easy installation.

- Leakproof.

- Easy installation.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Certification | CE Certified, ISO 9001:2008 |

| Application | Milk Pasteurizing |

| Weight | 1000-2000kg |

| Power | 1-3kw, 3-6kw |

| Driven Type | Electric |

| Warranty | 1year |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

Pasteurization is the heat treatment of a product to kill pathogenic bacteria and reduce enzymatic activity. The purpose is to make the product safe for consumption and to lengthen product shelf life. For its reliable functionality, it is well cherished among clients. Milk Pasteurizer works by giving heat treatment to liquids and other food products. The process of Pasteurization is used in the processing of milk by dairies. The process of milk Pasteurization has been hailed as the ultimate process of keeping the milk germ free and fit for consumption. Able Engineering is the leading manufacturer of Milk Pasteurizer and complete milk plants and dairy plants and milk plants and dairy plant equipment manufacturers in India.

- Skid-mounted for flexible relocation.

- Fully CIP prepared.

- Automatic control of pasteurization temperature & Automatic flow diversion

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Certification | ISI Certified, ISO9001:2008 |

| Feature | Easy To Use, Ergonomic Design, High Grade Material, High Working Efficiency, Longer Service Life, Low Maintenance, Simple Operation |

| Finishing | Polished |

| Steam Pressure | 0.5Mpa, 0.6Mpa, 0.7Mpa |

| Evaporation Capacity | 0-1000lts/h |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

Milk Plant Falling Film Evaporators are widely used in the Milk Plants and Dairy Plant industry. We manufacture highly efficient and durable Multi-Effect Falling Film Evaporators ( Milk Plant Falling Film Evaporators). Able Engineering manufacture Milk Plant Falling film evaporator according to required effects and capacity. Able Engineering is the leading manufacturer of Milk Plant Falling Film Evaporators & complete Dairy and Milk Processing Plant and Plant Machinery Manufacturer.

How it works

The evaporation process is used to concentrate whole milk, skim milk, whey, whey protein concentrate and permeate from membrane filtration modules. Water is evaporated through indirect heating. Product and heating medium (steam) are kept separate from one another by using a sheet of special steel. The heat released during the condensing of the steam is transferred to the product via the partition. It takes a large amount of energy to boil off water from a solution. This energy is often supplied as steam. To reduce this amount of steam needed, the evaporator is normally designed as a multiple-effect evaporator.

Two or more effects operate at progressively lower vacuums and thus with progressively lower boiling points. In such an arrangement, the vapor produced in the first effect can be used as a heating medium in the next effect. The result is that the amount of steam needed is approximately equal to the total amount of water evaporated, divided by the number of effects.

Some of the Products being processed on Milk Plant Falling Film Evaporator.

- Skim milk

- Whole milk

- Buttermilk

- Sweetened condensed milk

- Whole whey (sweet and acid)

- Greek yogurt whey

- Whey protein concentrates

- Whey permeate

- Lactose Mother Liquor (DLP)

- Refined lactose

- Salt whey and salt brine

- Milk protein concentrates

- Veal feed formulae

- Rinse recovery streams in fluid milk plants

- Dairy wastewater

- Lactose processing

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Material | Metal |

| Thickness | 0-10mm, 10-20mm |

| Certification | ROSH Certified |

| Application | Milk Use |

| Color | Shiny-silver, Silver |

| Capacity | 10000-12000ltr |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

Able Engineering is a well-known name in Milk Plant and Dairy plant equipment. These Milk Storage Tanks are available in different models to suit requirements. The standard models include vertical milk storage tank, horizontal milk storage tank, multipurpose milk tankers, etc. These tanks are used plants to store milk at low temperatures in the large diary. The tanks are made using the most ideal grade of stainless steel and mild steel, as required. Our range of milk storage tanks finds wide usage in dairies and food processing units. Our offered Milk Storage Tanks are acknowledged for their dimensional accuracy, fine finish, hygienic finish, and durability. Able Engineering is the leading manufacturer of Milk Storage Tank and Milk Silos and complete milk plants and dairy plants and milk plants and dairy plants equipment manufacturers in India.

Salient Features of Milk Storage Tank and Milk Silo

- Corrosion resistant

- Safe storage

- Easy to install

- Robust construction and durable in nature.

- Low maintenance.

- Leakproof.

- Easy to clean.

Specifications for Storage Tanks

- Capacity: 1000 liters to 50000 Liters

- Material of Construction: Inner S.S. 304, 316, Outer S. S. & M. S.

- Models Available In : Horizontal & Vertical, Single / Double Compartments

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Certification | CE Certified, ISO 9001:2008 |

| Application | Milk Supply |

| Weight | 100-120kg |

| Driven Type | Electric |

| Warrenty | 1 Year |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

Able Engineering is a leading Manufacturer of Milk Transfer Pumps. These pumps are famous for many names like Centrifugal Pump, Transfer Pump, Milk Transfer Pump, and Dairy Pump. The pumps of sanitary design would be used for the transfer of milk/ghee/butter having capacities up to 30 KLPH consisting of flange motor of suitable capacity with the hygienic sealing arrangement. The pump and drive would be integrated together with a SS shaft and the impeller (SS 304) would be fixed on the same shaft.

The milk transfer pump will be of sanitary design and provided with a mechanical seal. We manufacture, supply, and trade excellent Centrifugal Pump. We are using the latest technology to meet the variegated demands of clients.

- Modular Construction, High Interchangeability, Fast delivery.

- Versatile shaft sealing arrangement, Gland packing as a standard arrangement and option to us mechanical seal.

- Process type design results in minimum downtime.

- Closed impeller ensures high efficiency for a long period operation.

- Compact and robust design

Applications

- Milk, cream, buttermilk condensed milk.

- Fruit juice, beer, wine, sugar syrup.

- Vitamin solutions, sugar & confectionery.

- RO water, dm water, pure water. Water for injection (wfi)

- Vegetable oil, mineral oil, lube oil, etc.

- Pharmaceutical formulations, syrup, etc.

- Alkaline solution / alcoholic drinks.

- Acids, fine chemicals.

- Bottling plants, soft drinks & distillery.

- Food processing / liquid foodstuffs.

- Color dyes and pigments/paints.

- Descaling applications, paper & cement industries.

- Water treatment plants.

- Detergent, soaps, paste & shampoo.

- Textile sizing, dyeing & finishing systems.

- Natural cellulose fiber / synthetic fiber system.

- Hot & cold water pumping.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Capacity | 300 L |

| Design Type | Standard |

| Steel Grade | SS 304 |

| Features | Minimum maintenance, Optimum performance |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

Weigh Bowl is milk reception equipment. This bowl is used for weighing of milk received in cans at the dairy. The 3-way slope towards the discharge valve will be provided for free and complete drainage of liquid. Able Engineering is the leading manufacturer of Weigh Bowls and complete milk plants and dairy plants and milk plants and dairy plants equipment manufacturers in India.

- Construction: SS 304 Milk Strainer for the dumping of milk from cans.

- Finish: Sanitary 120 grit.

- SS 304 Milk Bowl fixed by 4 nos. hangers on the milk weigh scale.

- The make of bowl will be of Stainless steel 304 2mm thick sheet.

- All curvatures and corners are of a 25mm radius for sanitary purposes.

- The top edge of the bowl is folded to impart strength.

- The Bowl bottom sloping towards the outlet.

- Bowl outlet valve: Lift type disc valve for unloading of milk into the dump tank after weighing.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Certification | Ce Certified, Iso 9001:2008 |

| Weight | 100-500kg |

| Voltage | 380V |

| Condition | New |

| Power | 1-3kw, 3-5kw |

| Warrenty | 1 Year |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

We Manufacture Stainless Steel Cheese Press which are available in various production capacities, sizes, weights, and models as per clients. This machine is widely acknowledged by our esteemed clients owing to its long functional life and smooth operations. The customers use Cheese Press for pressing paneer and also use to make Paneer, Cheese, or Tofu from Coagulated milk in Food Processing plants and Dairy plants. This machine is widely appreciated due to its high tensile strength and rugged built as it is manufactured with the optimum quality material. Able Engineering is a leading manufacturer of Paneer Press (Cheese Press) and complete milk plants and dairy plants and milk plants and dairy plants equipment manufacturers in India.

Features

- All contact parts are of stainless steel.

- Perform excellently.

- Long durable life.

- Easy to Operate.

- Gives flawless service.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Certification | CE Certified, ISO 9001:2008 |

| Weight | 100-200kg |

| Voltage | 220V |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 1-3kw, 3-6kw |

| Driven Type | Electric |

| Warranty | 1year |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

Powder Mixer Venturi Machine (Powder and Liquid Mixer) used for mixing powder and liquid properly. Powder Venturi (Powder and Liquid Mixer) mostly used in milk powder plants, food processing plants, and Dairy processing plants. Able Engineering is the leading manufacturer of Powder Venturi (Powder and Liquid Mixer) and complete milk plants and dairy plants and milk plants and dairy plants equipment manufacturers in India.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Certification | ISO 9001:2008 |

| Finishing | Polished |

| Dimension (LxWxH) | 280x85x295mm |

| Rated Power | 1-3 KW, 3-5 KW |

| Packaging Type | Metal Sheet Box, Carton Box, Wooden Box |

| Loading Capacity | 5-10 Kg, 10-15 Kg |

| Machine Weight | 100-200 Kg |

| Specialities | Vibration Free, Unbreakable, Scratch Proof, Long Life, Heat Resistant, Excellent Quality, Corrosion Proof |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

We do Manufacture Roller conveyors using standard Precision bearings for heavy loads (250 kgs and above) and pressed bearings for lighter loads. Roller conveyor systems are used as mechanical handling equipment which moves materials from one location to another. These systems provide quick and efficient transportation for a wide variety of materials, which make them very popular for the material handling in the industries. Two types of Roller Conveyors are there one is Gravity Roller Conveyor which does not require any operational external power and another is Powered Roller Conveyor where the electric motor is provided for its operation. Components are designed to deliver heavy-duty usage and flexibility as well. These are fabricated with high-quality raw material to ensure their high standard durability. Roller Conveyors are used in Dairy Plant and Milk Plants for conveying plastic crates. Able Engineering is the leading manufacturer of Roller Conveyors and complete milk plants and dairy plants and milk plants and dairy plant equipment manufacturers in India.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Usage/Application | Industrial |

| Finish | Matt/Satin |

| Specialities | Durable Sturdy, Fine Finish |

| Pattern | Plain |

| Surface | Polished |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Certification | CE Certified, ISO 9001:2008 |

| Weight | 100-1000kg |

| Voltage | 220V |

| Condition | New |

| Rated Power | 1-3kw, 3-5kw |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Warrenty | 1year |

| Brand Name | Able Engineering |

Preferred Buyer From

| Location | Anywhere in India |

Able Engineering manufacture Paneer Vat (Cheese Vat) for Milk Plant and Dairy Plants. Paneer Vat (Cheese Vat) used for settling paneer (Cheese) and also for preparing paneer in various shapes such as round and square by processed milk. Provided machine is known for its user-friendly operation and less noisy functionality. We construct these Cheese vat with high-grade stainless steel as it provides robustness and durability.

Features

- Easy to Install.

- Leakproof.

- Easy operation.

- Easy to clean.