Saharanpur, Uttar Pradesh

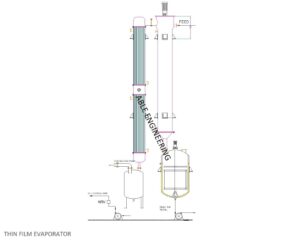

Agitated Thin Film Evaporator

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Certification | ISI Certified, ISO9001:2008 |

| Feature | Easy To Use, Ergonomic Design, High Grade Material, High Working Efficiency, Longer Service Life, Low Maintenance, Simple Operation |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

Agitated Thin Film Evaporator is best suitable for heat sensitive products where product drying time and the drying temperature are very critical and well-acknowledged among the buyers for its qualitative features. Our Agitated Thin Film Evaporator is for drying, vacuum distilling, and many more. We are counted as one of the leading Manufacturers and Exporters of Agitated Thin Film Evaporators.

Able Engineering‘s Agitated Thin film evaporators quickly separate volatile from less volatile components using indirect heat transfer and mechanical agitation of a flowing product film under controlled conditions. Either the vaporize component (distillate) or the concentrated component may be the product. Able Engineering provides turnkey solutions for Herbal extraction plants, Phytoextraction, and phytochemical plants.

How Thin Film Evaporator Works

The Product continuously fed into the Thin Film Evaporator above the heating jacket and spread onto the periphery of the distribution ring. The product then picked up by the rotor blades and immediately formed into a thin turbulent film on the heat transfer surface. The volatile components of the feedstock very quickly evaporated and flow counter-currently with reference to the feed, up towards the top of the evaporator to the rotating separator. Here, entrained droplets or foam knocked out of the vapor stream and return to the evaporation zone. The evaporated components then flow out of the evaporator into the condensation stage, column, or to another downstream process step.

For special applications co-current vapor/product flow used in which a separation vessel fitted at the bottom of the evaporator below the rotor in place of the normal rotor mounted separator and the upper vapor outlet nozzle.

Thin Film Evaporator Advantages

- Suitable to high vacuum distillation with very low residence time.

- Narrow spread

- Avoid product re-circulation and possible degradation

- Apt for viscous products

- Ideal for hazardous applications

Thin Film Evaporator Applications

- Vacuum Distillation

- Drying

- Solvent Recovery

- The Concentration of bulk drugs, enzymes, juice, milk product etc.

Looking for "Agitated Thin Film Evaporator" ?

Explore More Products